HOT-WELD - Aluminum welding rod

- 19.90€

- 19.90€

- Unit price

- per

Buy in pack & save!

30-day guarantee

100% Satisfaction Guaranteed or Your Money Back

Free delivery

From 50€ of purchase

![]()

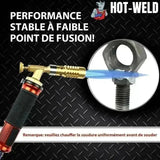

HOT-WELD: Easy welding of Aluminum.

This fine fusion rod allows good conduction thanks to the metal it contains, it has many qualities.

What can I fix with chopsticks?

Made of quality aluminum alloy, you can braze and repair almost all white metals as well as all other non-ferrous materials except stainless steel.

- Aluminum

- Aluminum alloys: 1060, 1350, 3003, 3004, 3005, 5005, 5050, 6053, 6061, 6951, 7000

- Cast aluminum alloys: 710.0 and 711.0

- Copper

- Zinc-based metals

It is also possible to braze dissimilar metals together, such as copper with aluminum or aluminum with galvanized metal.

What equipment is needed?

Thanks to their low working temperature, the baguettes melt at a temperature of 390°C!

It does not matter how the aluminum is heated, it is just necessary to reach and maintain 390ºC during work.

For most small jobs, a simple propane torch can be used.

How to properly prepare the part to be welded

Aluminum must be cleaned until the metal is exposed, removing rust (alumina) and all impurities (surface dirt, paint or coatings) the surface of the metal must be clean.

Important : always use a stainless steel brush, any other material will contaminate your aluminum and prevent adhesion).

It is this cleaning that guarantees optimal welding results.

Carry out your brazing within 10 minutes of brushing , otherwise the alumina will re-deposit.

The procedure is simple:

-

Start by cleaning your part and remove the alumina (or oxide layer) that could prevent proper fusion. To do this, use sandpaper or a wire brush. Using a drill can also help save time.

-

Heat your support to a maximum of 400°C using a propane blowtorch, with a power suitable for the part to be repaired.

- Use a baguette to weld quality aluminum for a neat and durable result. The rod must be positioned at an angle of approximately 90 degrees at the brazing point.

- Vigorously rub the solder into the repair area until the room temperature melts the rod.

IMPORTANT INFORMATION:

The properties of a special HOT-WELD™ aluminum welding rod

- The aluminum + copper core and the coating which gradually disappears as it liquefies but which plays a vital role in ignition by electrical conduction and protection of the molten pool.

- Welding carried out at low temperature with this type of rod is very resistant over time.

- From 380°C, the copper aluminum that constitutes it melts and immediately fuses with the metal .

- With this process, there is no risk of distortion of the base material. The welded supports do not deform and the resistance to wear and corrosion is very high.

No toxic fumes are released: neither toxins nor gases.

HOT-WELD™ aluminum welding rods are designed to ensure fast application to your project with minimal distortion.

EXAMPLE OF CUSTOMER ACHIEVEMENT ON AN ENGINE CRANKCASE

Tested and approved by hundreds of satisfied customers.

- Customer service available to answer all your questions.

- For professionals and individuals, a purchase invoice will be provided to you.

- 100% free tracked delivery !

- Internet exclusive

HOT-WELD™ Welding Rods are all you need in our online biker store !

*non-contractual packaging image sold without boxPolitique de livraison

- La livraison standard avec suivi est offerte pour toute commande supérieure à 50,00 €. Pour les commandes inférieures, les frais de livraison s’élèvent à 4,76 € (France et zone Euro).

Délais de traitement & de livraison

Délai de réception = Délai de traitement + Délai d’expédition

- Traitement : 1 à 3 jours ouvrables

- Livraison standard : 4 à 12 jours ouvrables

Nos équipes préparent et expédient chaque commande avec le plus grand soin. Certains articles nécessitent un contrôle qualité ou un acheminement depuis notre centre logistique, ce qui peut légèrement influencer le délai global de livraison. Le pays de destination influe également sur les délais, c’est la raison pour laquelle nos estimations indiquent 4 à 12 jours ouvrés. Dans tous les cas, chaque commande est suivie et livrée avec un numéro de suivi.

Retours & échanges

- Vous disposez de 14 jours pour demander un remboursement et de 30 jours pour effectuer un échange ou obtenir un avoir. Les échanges sont gratuits pendant 30 jours. Garantie 100 % satisfait ou remboursé.

- Les retours sont acceptés dans un délai de 30 jours suivant la réception de la commande (hors articles en liquidation, cadeaux, sous-vêtements, culottes, sacs et accessoires).

- Les articles doivent être neufs, non utilisés et dans leur emballage d’origine.

- Les frais de retour restent à la charge de l’acheteur, sauf en cas d’